News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

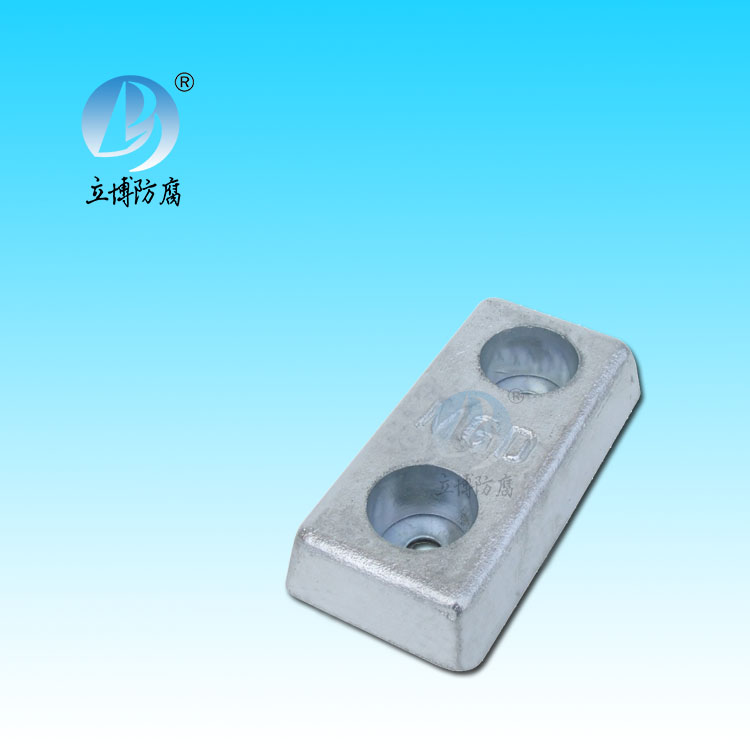

Life of magnesium anode

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

Different aspects of enamel quality and basic protection current test methods and characteristics are discussed in part II of the paper, the quality of the magnesium anode is discussed in part III of the paper, and the suggestions for the design of the magnesium anode are discussed in this section. They are now discussed together:

(1) If the quality of the enamel is good, the enamel defect is allowed to meet the requirements within the range and the basic protection current is less than 22.5mA/m2.

(2) If the mass loss rate of magnesium anode is 30g/m2/d as required in the third part (the data are obtained by side test in 3% sodium clawing solution, and the mass loss rate of magnesium anode is obtained by rapid side measure method).

(3) The water quality is within the normal range

(4) If the magnesium anode is insulated in the enamel liner (that is, only the enamel surface is considered).

⑤ If the weight of the magnesium anode is at least 200g/m2, the enamel surface area.

According to the above requirements, we can make the service life of the magnesium anode reach at least 2 years. The deposition of enamel defects, such as the formation of calcium carbonate, will of course lead to the reduction of the protective current and prolong the service life of the magnesium anode. We recommend that the magnesium anode be checked after 2 years of tank use (according to the German DIN4753 standard).

The life of magnesium anodes is very sensitive to water quality, especially the conductivity has an impact on cathodic protection (see Figure 3).

The life of the cathodic anti-corrosion system can be achieved by installing a larger and heavier magnesium anode. The increase in salinity leads to a lower resistance of the electrolyte and a greater current, which of course reduces the life of the sacrificial anode. We can set the consumption value. A low a value means that the magnesium anode's cathodic corrosion efficiency is low and has a high self-corrosion rate, and the service life of the magnesium anode is correspondingly reduced. Because of this, this trend is shown in Figure 4. There is no way to replace this conclusion obtained through field tests.

客服QQ

客服QQ