News

News

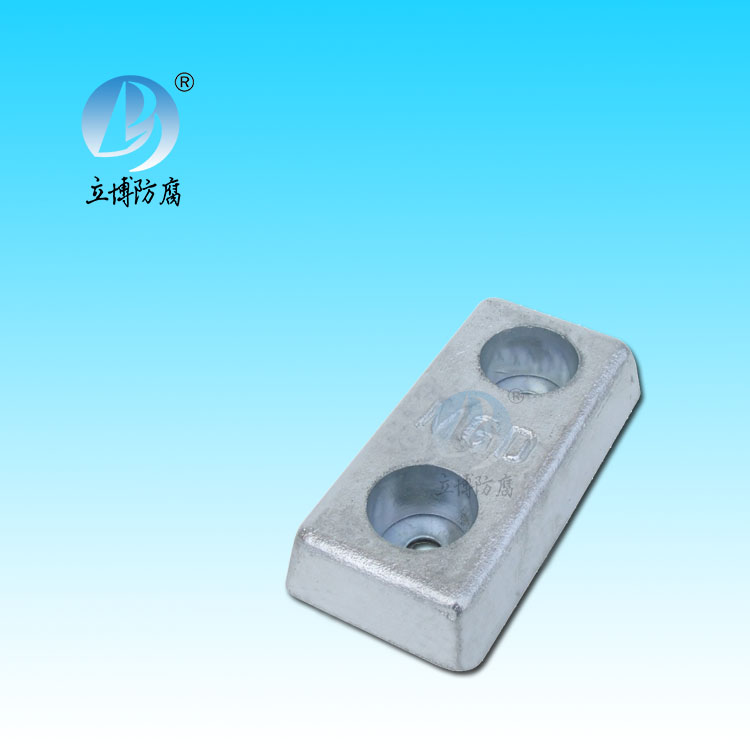

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

Trends in magnesium alloys

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

1. Light density, catering to the trend of fuel saving and lightness of home appliances;

2, easy machining cutting, relative to aluminum alloy to extend the tool life nearly 1 times the time, the surface processing finish is good;

3. Magnesium alloy castings have fewer pores than aluminum alloy castings;

4. Compared with aluminum alloy, magnesium alloy die-casting is less sticky, and workers are more labor-saving;

5, magnesium alloy forging relative to aluminum alloy, mold life is long, good maintenance, mold can use more than 250,000 mold;

6. Compared with aluminum alloy, magnesium alloy has less heat absorption from solid to liquid, and energy-saving in melting stage;

7. China is a large country of magnesium resources and raw materials are not disorderly. The state encourages the use of magnesium alloy;

8, magnesium alloy castings have shock absorption function, is a good choice for mechanical devices to reduce noise;

9, magnesium alloy heat transfer function is better, can do the idea and the whole heat dissipation shell;

10, the strength is relatively high, is about 70% aluminum alloy, can replace aluminum alloy, used in all aspects, good prospects;

11, magnesium alloy appearance quality, not easy to aging, can replace plastic, used in all aspects, good prospects;

12, magnesium alloy compared with plastic function, has electromagnetic shielding function, can be used for electrical field;

There are so many die casting magnesium alloys, but die casting magnesium alloys also have many problems

客服QQ

客服QQ