News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

Which a few kinds of production method of metallic magnesium have?

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

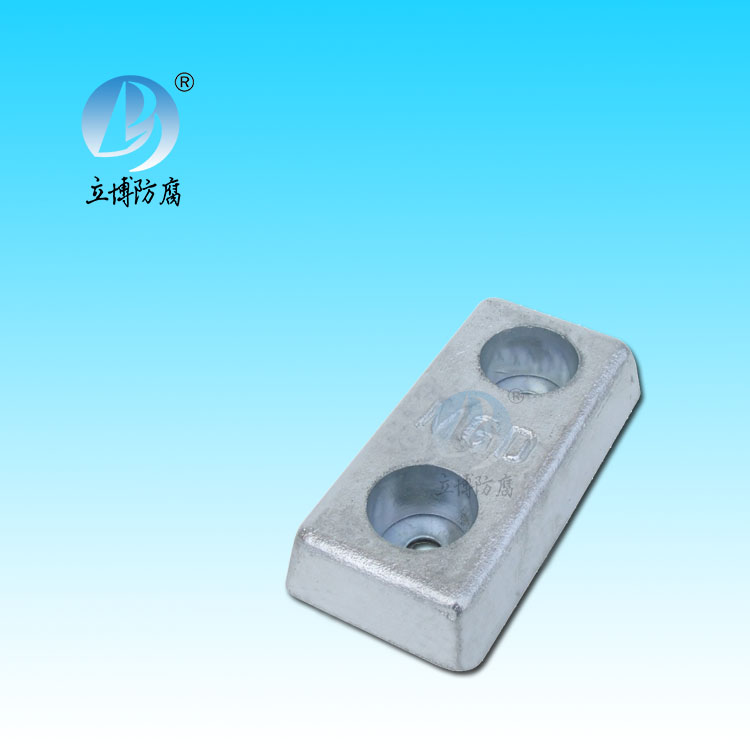

Magnesium anode: the production of magnesium in many countries, such as the United States, Russia, Na Wei, Canada, China and so on. In the process of production, each country adopts the magnesium refining method which is suitable for its own mineral resources and energy. At present, most countries use dolomite to produce magnesium metal. The methods of producing magnesium metal include melting salt electrolysis and thermal reduction. The former is the direct raw material for grasping magnesium, the latter is magnesium oxide.

There are many methods to produce magnesium metal by electrolysis, all of which take magnesium chloride as direct raw material. In the case of dolomite (because of the light environmental pollution caused by the extraction of magnesium from dolomite), the process of producing magnesium by electrolysis is to produce magnesium oxide first. Anhydrous magnesium chloride was prepared by re-chlorination, and finally magnesium metal was prepared by electrolysis. Dow, for example, uses seawater to make a slurry of sintered dolomite to precipitate Mg(OH)2. Then it reacts with hydrochloric acid to produce MgCI2, and then mixes with other substances to heat and electrolysis to produce magnesium metal.

The production of magnesium oxide is made of dolomite and seawater in Nawyboglon plant, and then it is made into balls with coke and magnesium brine. After drying, magnesium chloride is first made in the gripping furnace by chlorination, and then magnesium metal is prepared by electrolysis in the electrolytic cell at 750℃.

There are many other methods of producing magnesium metal by electrolysis.

The basic principle of silicon thermal magnesium refining is to mix ferrosilicon with the dolomite ore burned by the silk, and press it into small pieces, and put it into a steel distillation bottle. At a certain temperature and under the corresponding vacuum conditions, the silicon reduces magnesium oxide to generate metal magnesium vapor, and then crystallized magnesium by condensation.

There are three main methods to produce magnesium metal by silicon thermal method:

(1) Pijiang method: first, the dolomite satin is burned and mixed with ferrosilicon and fluorite. The magnesium vapor and other materials are generated, and then the magnesium vapor is condensed and recycled into magnesium ingot. The production of magnesium metal by this method has high energy consumption and heavy production operation.

(2) Magnethem: This method is used in a sealed electric arc furnace with a carbon-graphite lining and a fixed graphite electrode to reduce the calcined dolomite group with ferrosilicon, and add bauxite or alumina as a flux to produce magnesium metal. This method has low raw material consumption, high yield and less environmental pollution. Disadvantages are poor product quality, high silicon content, long non - production time.

(3) Bolgnao method (Bolgnao): the satin burning dolomite and ferrosilicon after pressing into the internal heat vacuum reduction furnace, with electric heating (reduction temperature is generally 1250cC), magnesium metal vapor in the external condensation magnesium metal.

In addition to the above mentioned methods, there are horizontal vacuum graphite resistance reduction furnace silicon thermal method, horizontal furnace silicon thermal method and so on.

客服QQ

客服QQ