News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

What are some misconceptions about magnesium?

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

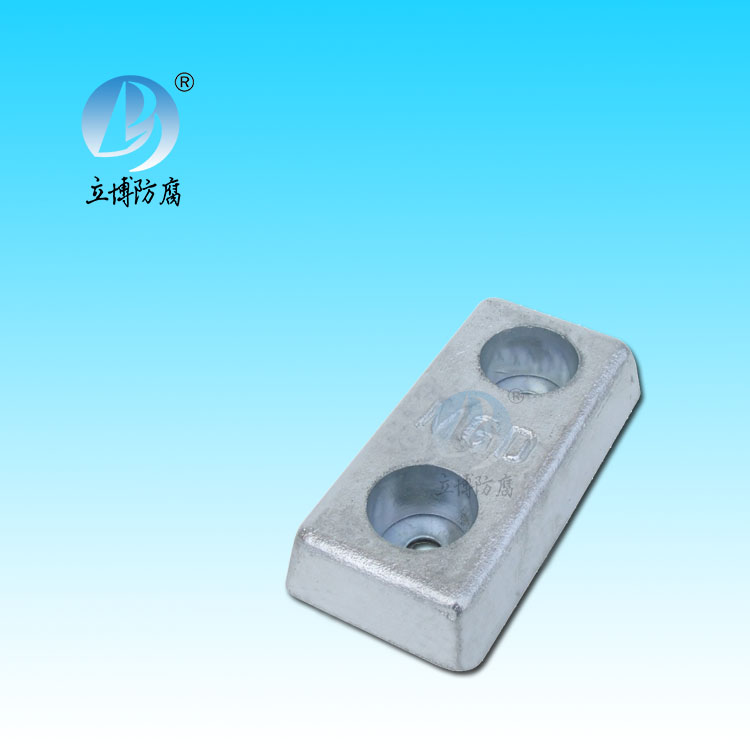

At present, it is easy to accept the advantages of magnesium, but there are still some confusion and even misunderstandings about some properties of magnesium, which need to be clarified. The common misconceptions of magnesium anode mainly include:

(1) Magnesium is a flammable metal. This misconception is due to the use of magnesium powder in many pyrotechnic products, thus forming this impression. In fact, magnesium ingots, magnesium die castings, magnesium profiles, will not burn until the temperature rises to the melting point (651 '). Easy to burn are magnesium powder, magnesium wire and magnesium foil.

(2) Magnesium is an easily corroded metal. Through theoretical and experimental studies, it is found that impurities such as iron, nickel, copper and the ratio of iron to manganese have a great influence on the corrosion resistance of magnesium alloys, so high purity die casting magnesium alloys such as AZ91 D have been developed in the United States. The corrosion resistance of AZ91 D is more than 100 times higher than that of AZ91 A, AZ9I B and AZ91 C. Most die cast magnesium alloy grades have exceeded the A380 aluminum alloy in salt spray corrosion resistance. In fact, magnesium is similar to aluminum in many ways. Prior to surface spraying, both surfaces should be pretreated to ensure affinity. Surface pretreatment is usually chemical treatment, which also improves corrosion resistance.

(3) Magnesium is a scarce metal. In fact, magnesium makes up 2.5 percent of the mass of the earth's crust, second only to aluminum, iron, calcium and potassium. In seawater, magnesium is second only to chlorine and sodium in content. It can be said that magnesium is inexhaustible.

(4) Magnesium is a difficult metal to form. People who have this misunderstanding think that the crystal structure of magnesium alloy at room temperature is tightly arranged and hexagonal, and there is only one movable slip system in the crystal, so it is difficult to form magnesium alloy. In fact, this is a one-sided understanding, in fact, magnesium alloy under compressive stress, at high temperature has good plasticity, magnesium alloy can be formed by extrusion, forging and rolling. Moreover, plastic deformation is only one form of magnesium alloys. Magnesium alloys can also be formed by casting, and the die casting properties of the alloy are better than most aluminum alloys.

(5) Magnesium is an expensive metal. Previously, an important factor restricting the use of magnesium alloys is that magnesium alloys are more expensive than aluminum alloys. But at present, the market price of magnesium alloy at home and abroad has been comparable with that of aluminum alloy.

It is worth noting that the price should not be compared by weight alone, but also the impact of different densities and the characteristics of magnesium alloys in processing and manufacturing on their cost. By comprehensive comparison, magnesium cannot be regarded as an expensive metal. ,

客服QQ

客服QQ