News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

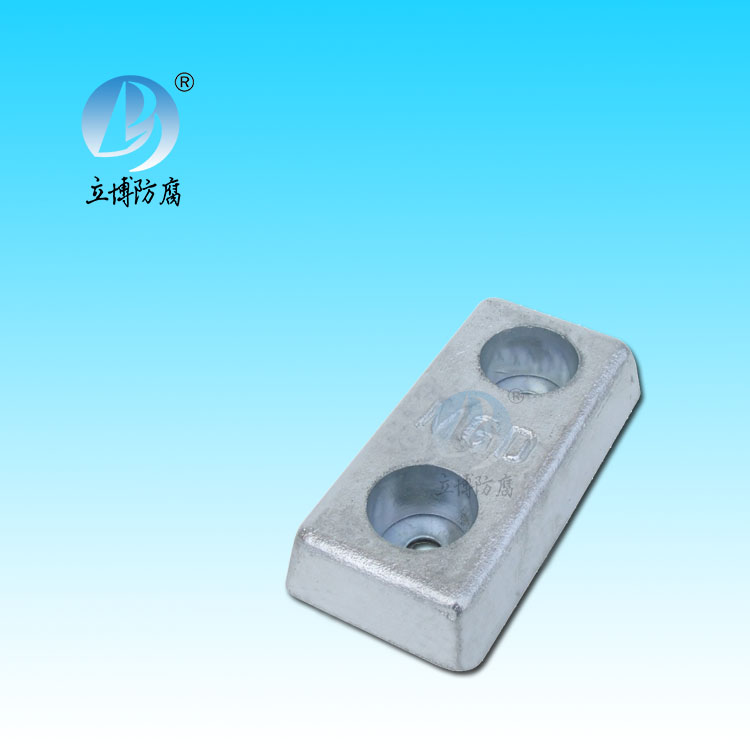

The use and advantage of magnesium anode

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

Magnesium anodes can provide effective cathodic protection for underground pipelines, storage, oil refineries, power plants, sewage treatment plants, buildings and well casing. It is suitable for areas where the surface soil resistivity is very high, or where the soil layer is shallow and there are high resistivity soil conditions, despite the relatively low resistivity. Under these conditions, large, shallowly buried anodes are required and far away from the structure to obtain a low enough far ground limit.

However, deep strata must have a low enough electrical limit to be suitable for the installation of a deep parallel anode. With the appropriate voltage applied, the magnesium anode can produce a certain current. Installing anodes in deep strata with low resistivity results in a very uniform current distribution along the structure compared to topsoil. Even the topsoil is perfectly suited for the design of shallow buried anodic beds. Magnesium anodes are more suitable in densely constructed areas. Because shallow-buried anodes are difficult to line. They can only be placed far away from protected pipelines and other structures and.

Since apogee is obtained along the depth direction. Magnesium anodes may be placed within the expropriation (ownership) of the pipeline. This is difficult to achieve for the usual shallow buried far anode ground bed system. As discussed earlier in this chapter. This remote property provides an optimal current distribution along the protected line and minimizes voltage gradient variation. These advantages make it possible to install high-current magnesium anode systems close to other facilities and structures without the adverse effects of shallow buried anode ground beds, such as interference with external structures, nitrogen embrittleness of sensitive steels, and cathode damage to coatings.

The total cost of cathodic protection can be reduced by installing anode systems at larger intervals. The compact anode system means less damage to other external facilities in the installation process, and other construction projects in the future are not easy to cause damage to the anode system. The reduction of the anode system means that there is less need to coordinate rectifier distribution and negotiate right of way. There are fewer vessels to maintain and fewer disturbance problems to examine, solve and monitor.

The maximum anode current can be uniformly discharged by installing multiple anodes in a carbon packed column. The highly dense carbon material in the magnesium anode bed ensures the maximum discharge current from the anode surface, thus increasing the life of the anode. Because of the high probability of encountering groundwater, it is possible to obtain a small loop resistance. A properly installed ventilation system minimizes the risk of gas resistance, and the anodic bed is easily wetted with potable water. The low loop resistance inherent in this anode system minimizes power consumption costs. It is important to note that many of the advantages of All magnesium anodic systems can be overblown if the design engineer intends to install too few anodic systems at too large an interval. In areas with external underground structures. A maximum output current of 30A is recommended for the magnesium anode.

客服QQ

客服QQ