News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

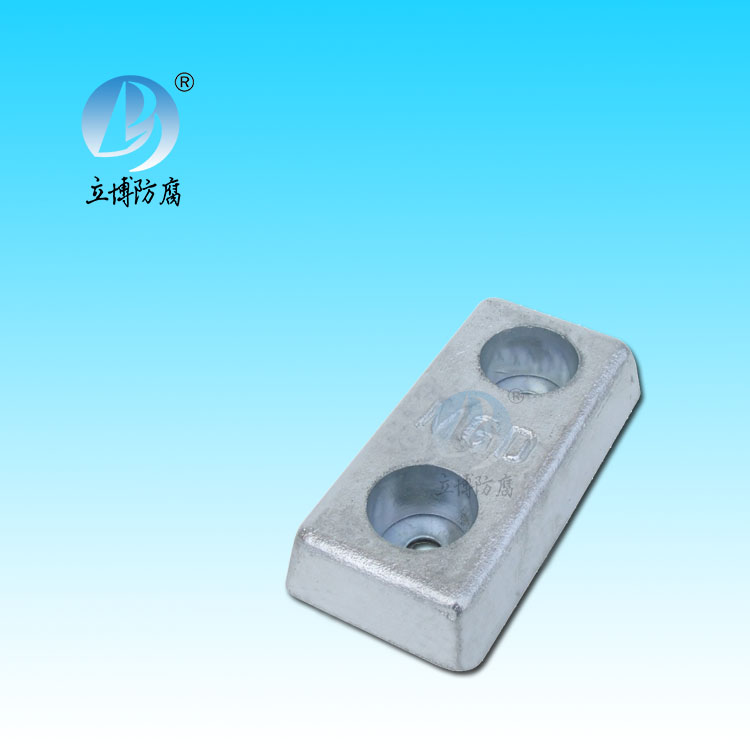

Foreign commonly used magnesium alloy models, specifications, custom

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

Magnesium weighs less than aluminum, has a specific gravity of 1.8, and is also of low strength. It is mainly used to make low-bearing parts.

Magnesium alloy also has a good corrosion resistance function, electromagnetic shielding function, radiation protection function, can achieve 100% recycling. Yield strength, elongation and aluminum alloy is not different.

The application of magnesium alloy is relatively wide, magnesium alloy is the lightest metal structure material used in aircraft, spacecraft and rocket missile manufacturing industry.

The characteristics of magnesium alloy processing

The processing process, erosion and mechanical function of magnesium alloy grade have many characteristics: light weight, good rigidity, corrosion resistance and size stability, impact resistance, wear resistance, good attenuation function and easy recovery; In addition, there are high thermal and conductive function, non-magnetic, good shielding and non-toxic characteristics. Gold medal number refers to the corresponding grade of magnesium alloy, mainly to identify the product representation of magnesium alloy.

At present, there is an international tendency to use the method used by the American Society of Testing Materials (ASTM) to mark magnesium alloys. Although the proportion of magnesium alloy is heavier than that of plastic, its strength and elasticity per unit weight are higher than that of plastic. Therefore, in the case of parts with the same strength, magnesium alloy parts can be thinner and lighter than those of plastic.

The magnesium alloy processing indicated by the magnesium alloy grade is a magnesium based alloy processing with the addition of other elements. The relative specific strength (strength to mass ratio) of magnesium alloy is the highest. Magnesium alloys oxidize and corrode easily in wet air, so surfaces need to be chemically treated or painted before parts are used.

Last letter:

The suffix letters A, B, C, D and E are identification codes, which are used to identify different alloys with different detailed constituent elements or slightly different element contents. Mainly used in aviation, aerospace, transportation, chemical, rocket and other industries.

In the elastic range, magnesium alloy can absorb half more energy than aluminum alloy when subjected to impact load, so magnesium alloy has good seismic and noise reduction function. Specific stiffness (ratio of stiffness to mass) is close to aluminum alloy and steel, much higher than engineering plastics. The lightest of the practical metals, magnesium is about two thirds as heavy as aluminum and a quarter as heavy as iron. It is the lightest metal in the practical metal, high strength, high rigidity. In addition, because the specific strength of magnesium alloy is higher than that of aluminum alloy and iron, the weight of aluminum or iron parts can be reduced without reducing the strength of the parts. Magnesium alloy parts have higher dimensional precision than high-pressure castings, and can be machined with high precision. With the development of related processing industry and manufacturing industry in China, China's own magnesium alloy brand will become one of the most influential magnesium alloy brands in the world. Therefore, reducing the weight of cars has a great impact on the environment and energy, and the lightweight of cars has become a certain trend. At present the most widely used is magnesium aluminum alloy, followed by magnesium manganese alloy and magnesium zinc zirconium alloy. The tensile strength of magnesium alloy castings is commensurate with that of aluminum alloy castings, generally up to 250MPA and up to more than 600 Mpa.

Application: Magnesium alloy is widely used in portable equipment and automobile industry to achieve the purpose of lightweight. The main alloying elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium.

According to relevant research, 60% of the fuel used by vehicles is consumed by the weight of the vehicle, and the fuel efficiency can be improved by more than 5% for every 10% reduction of the weight of the vehicle. When the weight of the car is reduced by 100 kg, the fuel consumption per 100 km can be reduced by about 0.7L, and the CO2 emissions can be reduced by 2.5g for every 1 L of fuel saved, and the annual emissions can be reduced by more than 30%. It is characterized by: small density (about 1.8g/cm3 magnesium alloy), high specific strength, large elastic modulus, good shock elimination, bearing the impact load capacity than aluminum alloy, organic matter and alkali erosion resistance function is good.

Magnesium alloy: Letters (two)+ numbers (two)+ Letters

The first two letters: The first letter: the alloying element with the greatest content;

2. An alloying element of a second content;

Number: indicates the content of two main alloying elements:

First number: the weight of the first letter %;

Second number: the weight of the second letter %.

For example, AZ91E means that the main alloying elements are Al and Zn, and their nominal contents are 9% and 1%, respectively. E means that AZ91E is the fifth part of the alloy series containing 9%Al and 1%Zn. The melting point of magnesium alloy is lower than that of aluminum alloy, and the die-casting molding machine can be better.

客服QQ

客服QQ