News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

Sacrifice anode cathodic protection

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

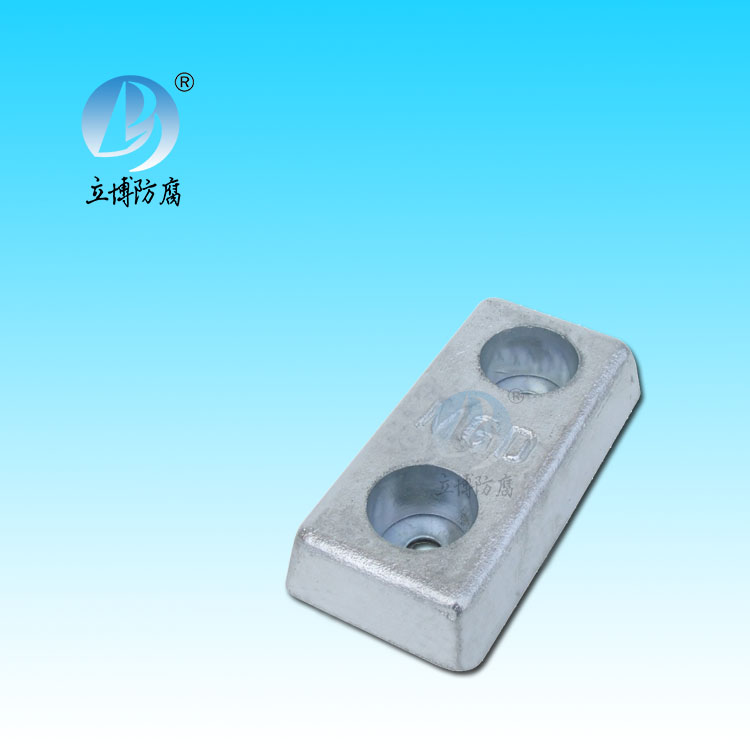

Corrosion of batteries caused by dissimilar metal contact. In this type of corroded battery, one metal is active relative to another and corrodes. In a sacrificial anode cathodic protection system. This effect is achieved by purposefully building a dissimilar metal battery. The battery is sufficient to counteract the corrosive effect of the battery in the pipeline. This can be done by attaching a very active metal to the pipe. This active metal will corrode. At the same time, the current will be released into the pipeline. Cathodic protection does not eliminate corrosion at the expense of anodic cathodic protection. Instead, corrosion of the structure is replaced by corrosion at the expense of the anode, so that the structure can be protected.

Under normal conditions, the current provided by the sacrificial anode is very limited. Sacrificial anode cathodic protection is generally used when the required protection current is small. Similarly, the disturbance voltage between the pipe steel and the sacrificial anode is limited. So. The contact resistance between the anode and ground must be low enough for the anode to release an effective current. This means that under normal installation conditions. Sacrificial anodes are used for soils with low electrical limit. The normal installation conditions referred to in this T. are expected to mean that the current emitted by the sacrificial anode device can protect a certain length of line. There are some examples. This is an application of the near-anode concept, which will be discussed later in this chapter. The design and installation details of sacrificial anodes are discussed further in Chapter 9.

In order to avoid the group dynamic voltage limitation associated with the sacrificial anode, the current from the external source can be forcibly applied to the pipeline through the ground bed and the source. See Figure 3-1. The most common power supply is the rectifier. The device converts alternating current into low voltage direct current. Rectifiers are often equipped with the function of reading the output of the current with reasonable precision. Although the maximum output voltage may be less than OV or close to loot/, most are in to-- SOt /. The current oil output range varies from less than l0A to several hundred amperes. This provides corrosion engineers with a wide selection of power supply capacities when designing forced-current cathodic protection expansion systems.

Any other adjustable DC signal can be used in a forced current cathodic protection system. Some of these are discussed in Chapter 10, and the detailed design of the rectifier equipment is discussed in Chapter 8.

Although the theory of cathodic protection is simple - a direct current is forced on the structure to reduce the corrosion rate. But there is an obvious question involved: how do we know that the buried structure is adequately protected? Her answer to this question is that various criteria have been developed over the years to allow us to determine whether adequate protection is achieved. The more commonly used criteria include measuring the potential between the pipeline and the ground. This measurement also allows a quick and reliable determination of the degree of protection achieved. In general, potential criteria are used to evaluate the change in structural potential relative to the environment. This change is caused by the cathodic protection current flowing from the environment (earth or water) to the structure. The maximum potential criterion and other criteria are discussed in detail in Chapter 4.

客服QQ

客服QQ