News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

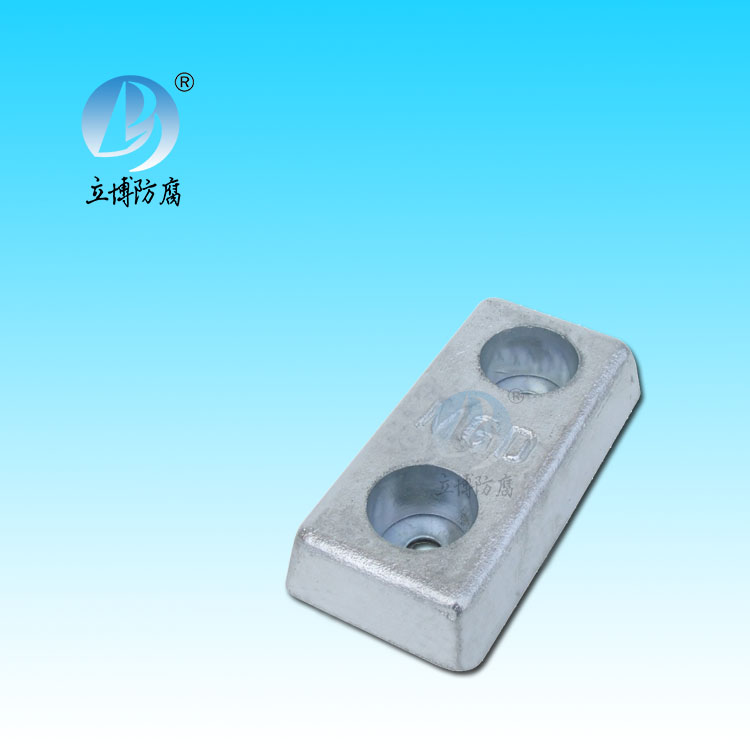

Mechanism of anodic oxidation of magnesium

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

Air force engineering university faculty of science studied the film forming mechanism of magnesium anode oxidation and some quantitative theory model: at the same time, through constant current flow of magnesium anode relevant data analysis, it is concluded that the breakdown voltage and electrolyte resistivity of numerical (LGP) the relationship is linear, and anodized film thickness for numerical Ind and voltage difference (V - V) also shows linear relationship, This conclusion is closely related to Ikonopisov and Albella N. This shows that the magnesium anodic oxidation mechanism is consistent with the electric breakdown film formation mechanism proposed by Ikonopisov.

By analyzing the working conditions of the cylinder liner and combining the principle of quenching the inner wall of the cylinder liner with equal ion beam, a kind of plasma quenching to improve the abrasion resistance of the inner hole surface of the cylinder liner has been developed. The industrial application results show that the process has a series of advantages, such as homogenization of lung damage on the inner wall of cylinder liner, improvement of engine power and reduction of engine noise. From the process of strengthening treatment, the process has the following advantages: Mill improves the processing speed without reducing the processing quality; (2) Can reduce the processing cost; (3) The thermal deformation of the treatment process is smaller. From the use aspect to dishes. It has the following advantages :(1) make the wear of the inner surface of the cylinder liner uniform, avoid the appearance of wear after the shape of the upper bell; (2) Replace the piston and piston ring. Reduce R cylinder volume; (3) Improve the sealing performance of the engine chamber; Reduce engine noise.

In the welding field, cast iron welding has always been difficult, in the welding of cast iron, in addition to consider the corresponding material, process and other factors. In addition, the damage of cast iron parts should be analyzed in detail, and the feasible welding process should be formulated to ensure the welding quality. The college of Mechanical and Electrical Engineering of Hebei Agricultural University analyzed the welding defects of cast iron and its causes, and put forward the solution of the welding defects of cast iron. The cold welding technology is used to repair the wear of the tile, the ramming of the cylinder and the crack of the cylinder block, etc. The reasonable technological methods and measures for the repair of different defects are given, and the experience for the repair and remanufacturing of the engine cylinder block is accumulated. In recent years, large and damaged engine blocks have been successfully welded. According to incomplete statistics, it has recovered economic losses of more than 4 million yuan for all kinds of enterprises and the army, and achieved good economic and social benefits.

客服QQ

客服QQ