News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

Characteristics of magnesium alloy forming process

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

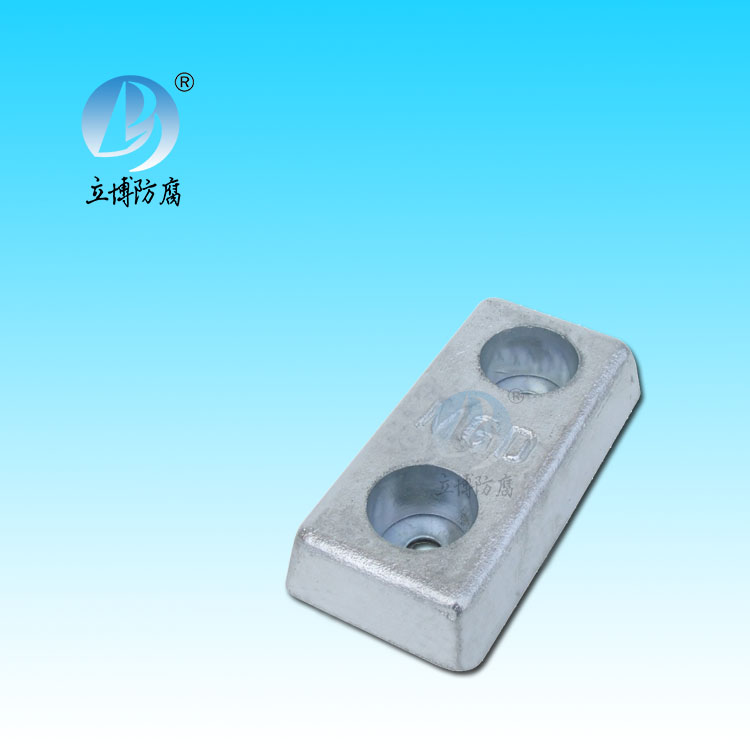

Magnesium anode specifications are divided into 2kg, 4kg, 8kg, 11kg, 14kg and 22k6 kinds by net weight. Its form is trapezoidal section. The 2kg anode reference length is 206mm, the 4kg anode reference length is 360mm, and the others are 700mm.

The steel core used for conducting electricity is made of steel bar not less than 6mm in diameter. The surface of the steel core shall be galvanized with an exposed length of 100mm. Anode matrix and steel core must be well combined, contact resistance should be less than 0.001 ω.

The surface of magnesium anode is a cast surface, which should be clean and smooth without obvious casting defects.

Magnesium anode should be stored in indoor warehouse, strictly prohibited from being contaminated with oil, paint and contact with acid, alkali, salt and other chemical products.

In the magnesium anode acceptance, the appearance and weight should be checked. The contact resistance, chemical composition and electrochemical properties of the steel core and anode should be sampled in batches. Spot check rate is 3%, but at least 3. If unqualified, double spot check, among them have another unqualified, then judge this batch unqualified. When the chemical composition is not qualified, but the contact resistance and electrochemical performance is qualified, can be used. Contact resistance test method is GB/T 4948-1985 Appendix B; Chemical composition analysis shall be carried out according to the standard method adopted by the supplier. Electrochemical performance was measured according to the test methods in Table 10-62.

The advantages of magnesium anode are as follows: the excitation electric pressure for cathodic protection of steel (-0.85V) is about -0.7V, the soil resistivity range is wide, the anode surface is not polarized, and the corrosion products are easy to fall off. Do not use in flammable liquid environment.

Construction of sacrificial anode protection

(1) the selection of anodes

| size①/mm | Weight/kg | Effective power/A·a | size①/mm | Weight/kg | Effective power/A·a |

| 47×(33+47)×1000 | 5.1 | 1.4 | 41×(29+41)×2000 | 7.5 | 2.0 |

| 60×(40+60)×1000 | 8.1 | 2.1 | 75×(61+75)×2000 | 27.4 | 7.2 |

Note: ① The upper and lower lengths of the trapezoidal section are in brackets.

The selection of sacrificial anodes is mainly based on the soil resistivity, soil salinity and the state of the covered layer of the protected pipeline. Table 10-67 lists recommendations for the selection of sacrificial anodes in soils. Generally speaking, magnesium anode is suitable for all kinds of soil environment, zinc anode is suitable for wet environment with low soil resistivity, while aluminum anode has not been universally recognized. It has not been advocated to be used in soil environment abroad, but has many practices in China. It is recommended to be used in the environment with low resistivity, moisture and chloride.

| Soil resistivity/(Ω·m) | Recommended sacrificial anode |

| >100 | Sacrificial anodes should not be used |

| 60~100 | High potential pure magnesium or magnesium-manganese magnesium anode |

| 15~60 | Magnesium aluminum zinc manganese series magnesium anode |

| <15 | Mg-al zn-Mn series magnesium anode or zinc alloy anode |

| <10(含Cl-) | Anode of zinc alloy or aluminum zinc series alloy |

客服QQ

客服QQ