News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

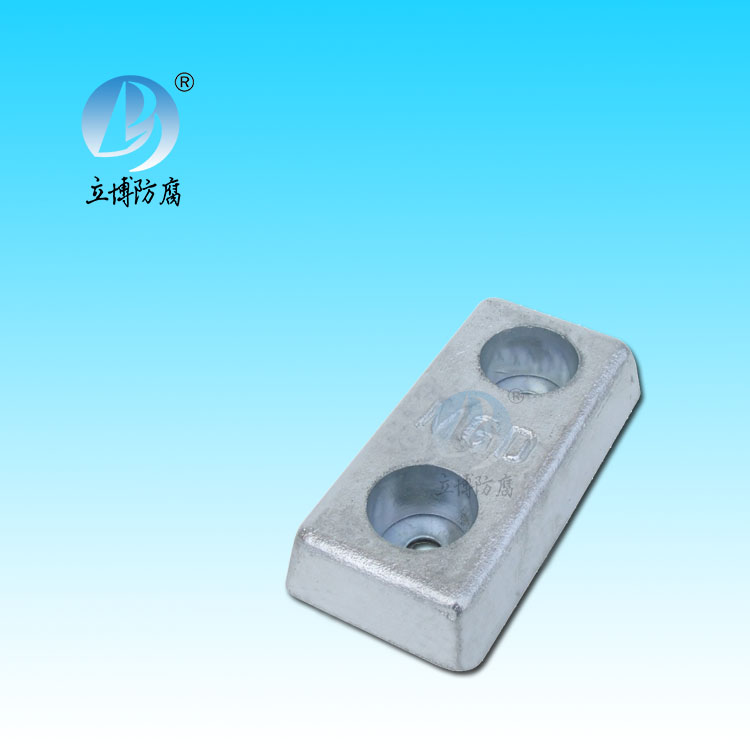

Magnesium alloy sacrificial anode

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

The current efficiency of magnesium anode is about 50% and may be lower due to environmental influence. Generally should not be used for soils with a resistivity less than 10 ohms. M environment.

Magnesium anode has high driving voltage, low current efficiency and high cost. There may be no significant change in the anode's open circuit potential or in the pipe potential measured at the current point. When the residual amount of sacrificial anode is 15% of the initial weight, it is considered that the anode has failed, so the utilization rate of the anode is generally 85%.

A list,

Magnesium alloy sacrificial anode

. Magnesium anodes may be used with resistivity up to 20 ohms, depending on the shape and electrode potential (open circuit potential). A soil or freshwater environment of meters to 50 ohms. When the temperature rises, the erosion is intensified and the efficiency is reduced. Therefore, in salt water or salt water, the use temperature should not exceed 32℃; In fresh water, should not exceed 45℃, in seawater, its life is very short, should not be used. When the soil resistivity is high, the anode output current is small, the anode surface is easily passivated, further increase the grounding resistance, so that the anode output current is further reduced. When the soil or water is low in salt, the current output is small and, therefore, the erosion itself is relatively large. The potential of the high potential magnesium anode is -1.75V CSE and the driving voltage is 0.85V. The potential of the low potential magnesium anode is -1.55V CSE and the driving voltage is 0.7V. The operating temperature can reach 100℃.

Chemical composition of magnesium alloy anode

Table 1-1

Element standard type magnesium manganese type

Al5.3 ~ 6.7 0.010 or less

Zn2.5-3.5 -

Mn0.15 0.600.50 ~ ~ 1.30

Fe acuities were 0.005, 0.03 or less

Ni acuities were 0.003, 0.001 or less

Cu acuities were 0.020, 0.020 or less

Si 0.10 or less -

Mg allowance allowance

Electrochemical properties of magnesium alloy anodes

Table 1-2

Performance standard type mg-Mn remarks

The density of g/cm after 1.771.74

Open circuit potential V-1.55-1.70 relative to CSE

Theoretical capacitance A.h/kg22102200

Theoretical current efficiency %5550 in seawater under the condition of 3mA/cm2

The actual current efficiency %≥5040 in the soil, under the condition of 0.03Ma /cm2

Actual capacity A.h/kg1110880

Calculation method of magnesium alloy anode consumption

W = (I * t * 8766)/(U * Z * Q)

I Anode current output (Amps)

T Design life (YRS)

U Current efficiency (0.5)

Z Theoretical capacitance (2200Ah/kg)

Q Anode utilization rate (85%)

W Anode weight (Kg)

Five, magnesium alloy anode application

1. Main performance:

It is an ideal sacrificial anode material for cathodic protection of metal structures in soil and fresh water with high electrochemical performance, uniform anode consumption, long life and large power generation per unit mass.

2. Scope of use:

In sacrificial anode cathodic protection methods, magnesium anodes can be used for resistivity up to 20 ohms. A soil or freshwater environment of m to 100 o. m.

Specifications for magnesium alloy anodes

No. Magnesium Weight KG

14-0.2350 * * 80 (75 + 85)

28 + / - 0.2700 * * 80 (75 + 85)

311 + / - 0.3700 * * 90 (90 + 100)

414 + / - 0.3700 * * 105 (100 + 110)

522 + / - 0.3700 * * 125 (130 + 150)

客服QQ

客服QQ