News

News

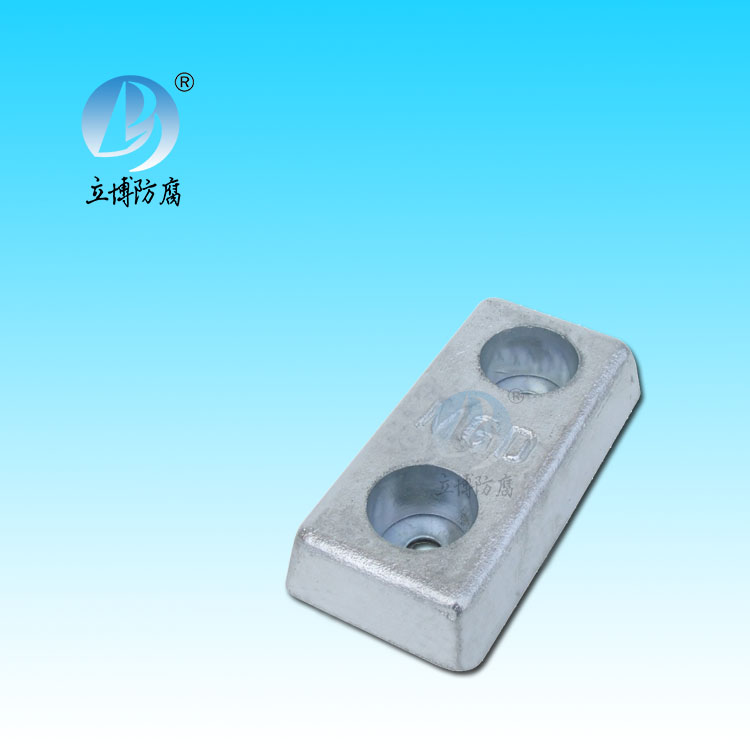

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Company News

The harm of anode effect in aluminum electrolysis production is analyzed

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

At present, some anodic effect coefficients in foreign countries are lower than 0.1 times/tank day. Understanding the development of aluminum industry in today's world, especially the famous aluminum expert Haupind's "aiming zero effect "[4] is of great benefit to the improvement of the overall level of aluminum electrolysis in China.

(1), with a shovel to extinguish the anode effect. Effect rods are about 2 to 3 meters and 2 to 4cm in diameter. However, with the improvement of anode quality and the application of intelligent trance control computer system and point blanking technology, the anode effect is becoming more and more small, so the traditional view can not adapt to the production of modern electrolytic cell. Considering the current anode quality in the sea, physical function of alumina and other factors, it is possible to control the anode effect below 0.2 times/tank day.

The root cause of PFCs=CF4+C2F6 is the anode effect (AE), but Korea has only paid attention to control technology for a long time.

2) Make sure there are enough electrolytes in the electrolyzer to prevent electrolyte atrophy. Take our electrolytic cell as an example: an effect time of 5min, the molecular ratio of uniform rise 0.1. About 10 ~ 20kg of aluminum fluoride was lost.

Take 300KA intermediate feeding prebaking tank as an example: effect coefficient 0.3 times/tank day, effect time 5min, current efficiency 93%, one anode effect less primary aluminum production: 300×0.3355×5÷60=8.4kg, tons of aluminum power consumption increased 158kwh,

In production, when the anodic effect occurs, the temperature of the electrolyte rises sharply from the normal value of 940℃ ~ 955℃ to 980℃ ~ 990℃, and the furnace side melts and becomes thinner, increasing the possibility of corrosion of the carbon block on the side.

1. Mechanism of anode effect

With the increasing importance of environmental protection today, the anode effect should be strictly controlled in the production of aluminum electrolysis, especially in the production of large pre-baked cell. As long as the condition of the electrolytic cell is normal, there is no need to effect.

4) Stable power supply, reduce current fluctuation, select the best current intensity. Causes AE to occur. Individual trials have shown that reducing the number of effects is more effective than reducing the time of effects in reducing PFCs occurrence.

Most of this energy is converted into heat energy in production, so that the temperature between the electrolytic cell poles rises sharply, and then the conduction around the rising sun pole, so that the temperature of the electrolytic cell rises, causing a large amount of volatilization of aluminum fluoride in the electrolyte. The critical current density decreases with the decrease of alumina concentration (because Nc tends to 1 with IC). With the decrease of alumina concentration, bubbles are generated on the anode, resulting in the increase of electrolyte surface tension and the increase of anode effect overvoltage.

The above three methods are commonly used in the production of aluminum electrolysis, especially the self-baking cell. Increase the effect distance time. In the production of aluminum electrolysis, strict control of anode effect is the requirement of The Times. From the 1950s to the 1990s, due to excessive cutting and deforestation, the fragile forest vegetation was severely damaged. The occurrence of land desertification and dust storm is the biggest revenge of nature to human cutting and deforestation. With the implementation of the policy of returning farmland to forests and planting trees and grass, the state has formulated a series of relevant policies to seriously stop the phenomenon of cutting and cutting. The state has invested a huge amount of money to restore the forest vegetation, and closed the mountains and planted trees and grass in the severely damaged areas.

8) Pay attention to the roasting start work of the electrolyzer to ensure that the electrolyzer can set up the polymer furnace in the specified time.

4. Conclusion

9) Improve the working quality of the anode, standardize the operation procedures, improve the replacement speed of the anode, and reduce the interference to the electrolytic cell. The extinguishing method of anode effect in production is: Will effect the stick - (about 2 ~ 3 m 2 ~ 4 cm in diameter) branches inserted in the liquid aluminum anode bottom palm sticks burning out of gas film, clean the bottom of the anode, actual it is the burning liquid aluminum, the whole process lasts about 3 ~ 5 minutes, while the electrolytic electrochemical process is resting, which is electrolytic worker often said "don't produce aluminum effect time, And it costs electricity. "Why. Is the only way to extinguish the effect. When new alumina is added, oxygen is precipitated on the anode, oxygen reacts with carbon powder, and the surface of the anode is quiet, the resistance is reduced, and the electrolytic process tends to be normal.

1860 trough days per month, a total of 1860×0.3=558 effects

Taking this enterprise as an example, the anode effect coefficient is controlled at 0.3 times/tank day

At present, the production of aluminum electrolysis in China is developing rapidly. In 2003, it has exceeded 520 tons, and it has become the no.1 aluminum producer in the world. The use of effect rod has increased sharply.

Based on the comprehensive analysis of the actual situation of the pre-baking tank in China and the experience of the control of the anode effect on the pre-baking tank abroad, the author thinks that the control of the anode effect and the reduction of the number of the anode effect should be improved in the following aspects.

Haupin[4], an internationally renowned aluminum expert, thought that the occurrence of PFCs was linearly related to AE minutes per day and voltage level. However, the analysis showed that the amount of PFCsd hair did not show a specific effect of longer effect time and more hair under high voltage effect.

3. The way to control the anode effect

Our country is a country with very little forest coverage.

There are three ways to extinguish the anode effect in aluminum electrolysis production:

2.3 Harm of anodic effect to forest

Our country is the signatory country of international "Kyoto agreement", reduce greenhouse effect, protect atmospheric environment is obligatory responsibility.

2.2 Harm of anode effect to environment

The traditional view is that the anode effect can be used to separate carbon slag, clean electrolyte, supplement the heat deficiency of electrolytic cell, and precipitate.

The harm of the anode effect is worth our attention, especially its damage to the environment and forest, which we have not considered in the past. The pre-baking tank is produced by multiple groups of anodes, and the method of large rake and leakage shovel extinguishing anodes effect has lost its effect.

The critical current density is a function of dissolved alumina concentration. However, it is also affected by electrolyte activity, electrolyte temperature, anode size (including the interface change of the anode after consumption), and chamber volume. Ensure stable production.

(3), use the effect rod (stick) to extinguish the anode effect.

3) Improve the insulation effect of electrolytic cell, reduce heat loss, appropriately increase the thickness of insulation material on the anode. Keep the electrolytic cell production is not disorderly. The sharp increase of voltage makes the series current fluctuate and affects the output of electrolytic cell. Power consumption increases. "Zero effect" treatment is the future development direction of aluminum electrolysis production. As for the aluminum electrolysis manufacturers in western China, the anode effect should be strictly controlled in the production of aluminum electrolysis to minimize the use of the effect rod

At present various aluminum plant effect good basic is supply by the market, some people in order to seek personal interests, hacked or even steal to cut down trees to make aluminum electrolytic required effect good sell electrolysis plant, so the effect of aluminium electrolysis anode rod use has increased dramatically, must encourage some people seek personal interests, and the behavior of the deforestation of trees, it will bring a disaster to the national forest. Therefore, severe loss of liquid aluminum was caused. "Zero effect" treatment is the future development direction of aluminum electrolysis production. Has fallen out of line with the demands of our times. Nowadays, the western developed countries have very strict environmental requirements for aluminum electrolysis. Accepted by electrolysis scientists. The author will elaborate from several aspects. Therefore, in the control of harmful gas emissions, will be strengthened in the future. If not controlled, it will surely bring severe damage to the forest.

6) Change the treatment idea of anode effect, correct the relationship between electrolytic cell and effect, and set up the treatment idea of "no effect is necessary as long as the condition of the cell is normal".

Analysis of the harm of anode effect in aluminum electrolysis production

. And the governance methods are extremely biased. The Times are developing and the society is improving. In the production of aluminum electrolysis, the source of effect rods must be strictly controlled.

2.1 Harm of anode effect to production

In the production of aluminum electrolysis, the harm of anode effect is not only shown in the harm to production, but also the harm to the ecological environment is extremely severe. Set the effect distance time above 100 hours.

Therefore, in the production of aluminum electrolysis, as long as the electrolytic cell production is normal, the anode effect as little as possible. Aluminium electrolysis produces an old understanding of the anode effect.

(2), with a large rake to extinguish the anode effect.

It takes about 2 ~ 3 effect rods to extinguish one effect daily, 558×3=1674 effect rods per month if it takes 3 effect rods, and about 1674÷30×12=672 bundles per year if it takes 30 effect rods per bundle. In addition, it takes about 900 ~ 1000 bundles per year if the factors such as lifting busbar and pressure load are added. Still stay in the traditional control of fluoride salt. Like our company's 75KA intermediate blanking pre-baking tank, the author thought that the electrolyte level should be ≧18cm. Aluminum level & lt; 22cm.

1) The premise of the use of sand alumina, improve the processing of the cutting track system, to ensure that raw materials are sufficient, ensure the electrolytic cell feeding mouth unimpeded, to prevent uneven cutting. Since both CF4 and C2F6 are generated at the beginning of the anode effect, not only the number of anode effect is doubled, but also the effect time is greatly shortened after the electrolytic cell develops to the middle prebaking cell.

7) Optimize the lining structure of electrolytic cell, adopt semi-graphite cathode carbon block, adopt new dry anti-seepage material, improve the insulation effect of cathode bottom, electrolytic cell measuring part adopts silicon carbide composite material. Maintain appropriately high electrolyte levels.

Nc - 0.00004308 Tin I} {IC/IC -

I -- maximum current density at any anode;

Ic -- critical current density;

F- Faraday constant;

T- temperature, 0K;

R-gas constant;

Where Nc- produces the concentrated overpass voltage of the anode effect;

Zc=RT/Fin{ic/ic-I}

The mechanism of anode effect is [4] :

Up to now, there are many different opinions about the mechanism of the anode effect, but the best explanation of the anode effect is the "anode process change theory". [1] : Anode effect occurred because follow the electrolytic process, oxygen ion in electrolyte gradually reduce, when after reaching a certain degree, has the fluoride precipitation and anode effect natural charcoal of fluoride, charcoal of fluoride in decomposition and precipitation of subtle granular, the granular attached to the anode surface, prevents the electrolyte and anode contact, make the anode, electrolyte not well damp Just like water cannot wet the oil coated surface, the formation of a layer of bad conductive gas film between electrolyte and anode, anode overvoltage increases, causing anodic effect. At present, almost all of the self-baking tanks have been transformed into intermediate pre-baking tanks.

In the production of aluminum electrolysis, the anodic effect is also accompanied by the generation of PFCs(CF4.C2F6) gas which is destructive to the atmospheric ozone layer.

5) The use of computer intelligent trance control technology to control the electrolytic cell, improve the hanging rate, reduce manual times.

2. Sacrificial anode effect harm

This viewpoint can better explain the reason of the anode effect. Keep the thickness above 12cm.

客服QQ

客服QQ