News

News

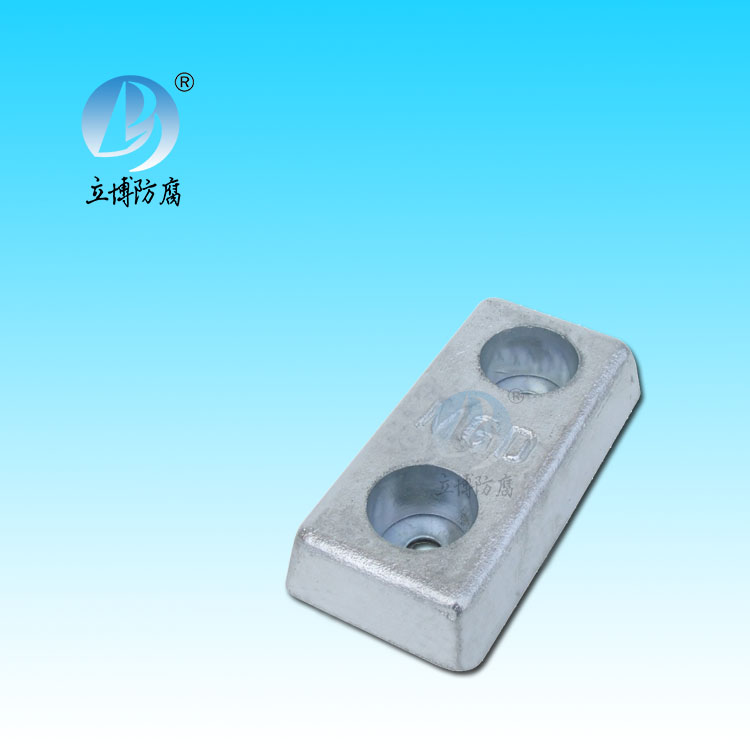

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Q & A

Aluminum alloy anodic oxidation process nitrate and sulfation throw what is different. Why do we have a certain percentage of phosphoric acid? Instead of using diluted sulfuric acid

- Author:Libo

- Source:wwww.hellobodies.com

- Date:2021-06-11

- Click:0

Triacid works better.

They have different effects. Phosphoric acid and sulfuric acid react on the surface, while nitric acid produces passivation, which slows down the corrosion rate. Phosphoric acid forms a viscous diffusion layer containing aluminum salt on the surface, which increases the thickness of the sag and protects the sag.

You can use diacid, phosphosulfuric acid and phosphonitric acid.

If only sulfuric acid or nitric acid is used to make the surface bright, the effect is limited

客服QQ

客服QQ